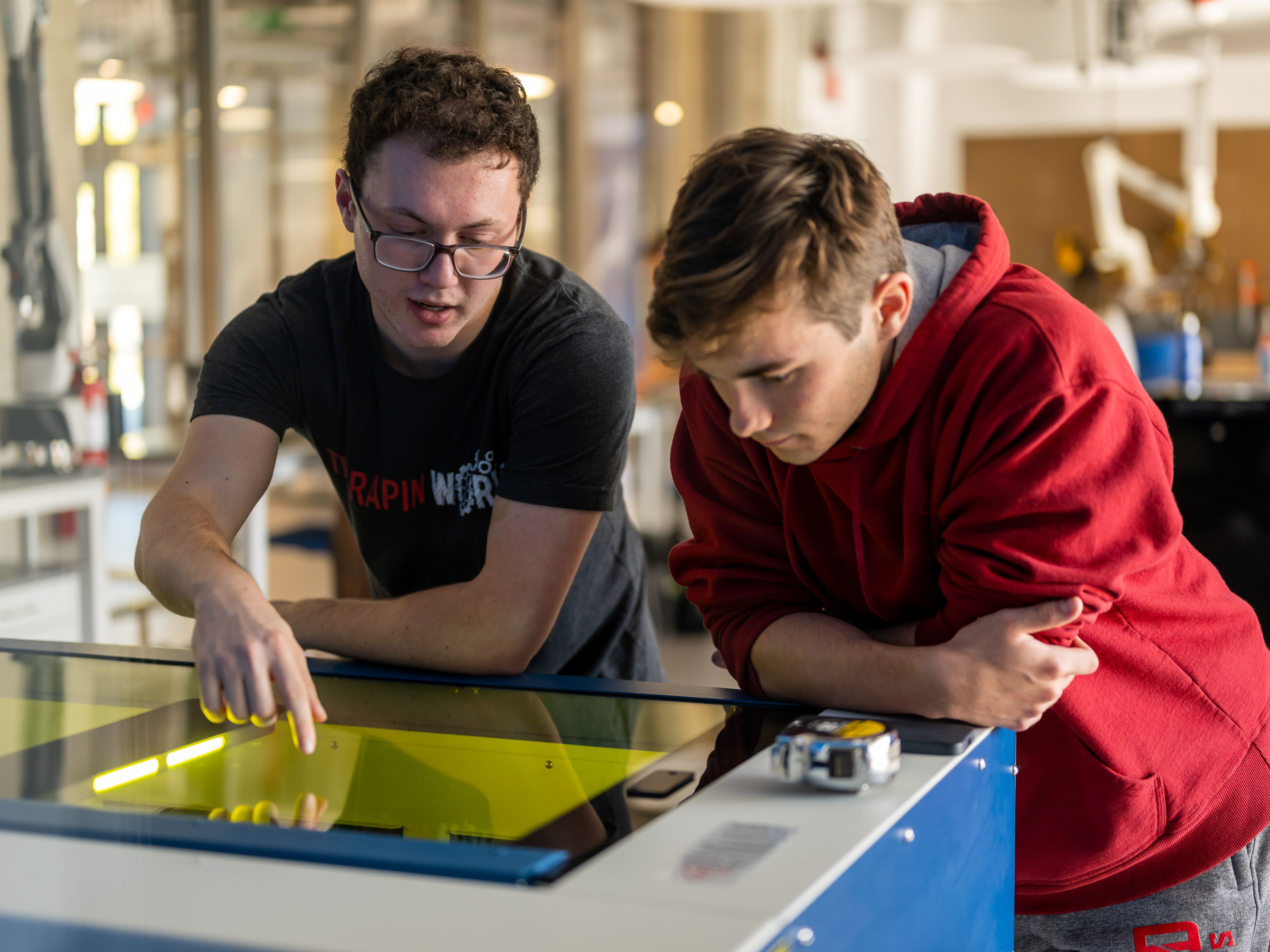

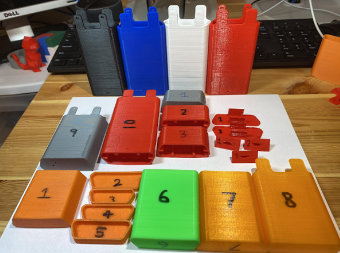

In high school, I participated in the Northrop Grumman High School Involvement Partnership (HIP) Program. I was tasked with coming up with an idea of something I could invent. I wanted to make the project related to me, so I decided to innovate on the epinephrine injector. I have a life-threatening peanut allergy, which requires me to carry an epinephrine injector with me incase of an allergic reaction. This can be a stressful ordeal, especially for younger kids, so I created a device that automatically sends a text message to an emergency contact if an allergic reaction is happening. This was my first project that was intended for community service. It works by using some electronics concealed in a custom case extension that I designed. The device uses a small switch that opens when the epinephrine injector is removed from the case. Once this happens, the circuit board sends a message to my phone, which triggers text messages to be sent.

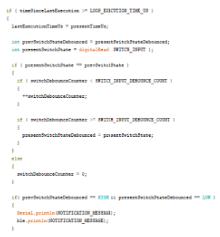

This project involved a considerable amount of time dedicated to iterating the case design and perfecting the software. At the time, I was unfamiliar with Arduino coding, so this was a great experience to learn different coding techniques such as debouncers. 3D printing has always been a passion of mine, and this was the first real project that I was able to showcase my skills. I used my ingenuity and determination to develop a product that ended up being 55% cheaper and 75% smaller than existing products on the market. Choosing a topic that was personally related to me was a great way to support others with allergies and make a lasting impact on the world. I hope that one day I will be able to continue working on meaningful projects that can help my community.

This project offered a diverse range of skills and learning experiences. It involved the use of programming languages such as Swift, C++, and Python for app development and coding the Arduino-based controller housed within the case. Additionally, 3D-printing played a crucial role in physically prototyping case designs crafted in both Inventor 2019 and Fusion360. The 3D printer utilized was one I personally built during my sophomore year in high school. The project required proficiency in technical areas such as soldering, basic electrical knowledge, and CAD designing. As an intern, I had the sole responsibility for the project and had the privilege of leading a team of experienced engineers who assisted me in successfully bringing the project to completion.